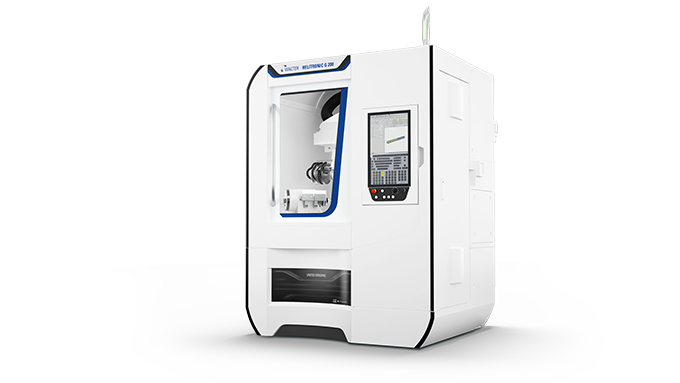

COMPACT – ACCURATE – RELIABLE

The HELITRONIC G 200 tool grinding machine impresses with an innovative machine concept with a footprint of less than 2,3 sqm. The machine offers tool grinding at its best: Production and re-sharpening of rotationally symmetrical tools in the diameter range of 1 to 125 mm, with a maximum tool length of 235 mm and a tool weight up to 12 kg. Maximum grinding wheel diameter is 150 mm.

C-frame construction

The C-frame construction and the mineral cast bed with its high weight and extreme rigidity converts the high dynamic performance of the digital drives into low-vibration grinding precision.

Belt-driven spindle

The belt-driven spindle with two ends can take up to six grinding wheels. The different grinding wheel sets are allocated to the relevant spindle along with the wheel measurement data.

“Top loader” option

This space-saving and inexpensive automation solution is integrated directly into the machine envelope. Featuring an automatic teaching capability setup times are reduced to a minimum. Depending on the tool diameter, the Top loader offers a maximum of 500 places for tools.

Mechanical axes

| X axis | 305 mm |

| Y axis | 218 mm |

| Z axis | 475 mm |

| Max Travel Speed X, Y, Z | 15’000 mm/min |

| C axis | ± 200 ° |

Grinding spindle drive

| Max. Spindle Power | 9 kW |

| Max. Number Of Revolutions | 10.500 /min |

| Max. Grinding Wheel Diameter | 150 mm |

Workpiece Data

| Workpiece Length | 195 / 235 mm |

| Workpiece Diameter | 1 (3) – 16 (125) mm |

| Max. Workpiece Weight | 12 kg |