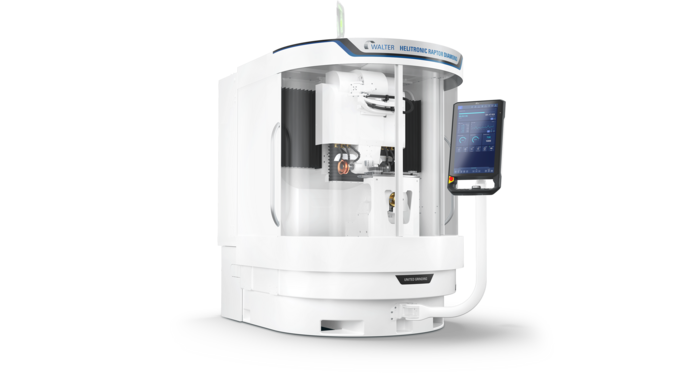

Flexible “Two-in-One” erosion and grinding entry-level machine

The tool eroding machine HELITRONIC RAPTOR DIAMOND is the cost-effective and performance efficient entry-level solution within our erosion portfolio when it comes to eroding PCD and CBN tools and grinding HSS and carbide tools in a single clamping cycle, on a small footprint, as well as for large tool diameters! The machine erodes tools with a diameters of 3 to 400 mm, a tool length including End Face Operation up to 270 mm and a weight up to 50 kg.

Gantry design

The WALTER gantry design in cast iron with its good damping properties ensures optimal tool surfaces.

Linear axes

The tool eroding machine has three linear axes X, Y, Z with ball screw. The maximum travel speed is 15 m/min.

Belt-driven spindle

The HELITRONIC RAPTOR DIAMOND has a HSK belt/driven spindle with two spindle ends for up to three electrodes and up to three grinding wheels, alternatively up to six grinding wheels

Fine Pulse Technology

The eroding machine is equipped with the latest eroding technologies for a stable and fast eroding process. This ensures a perfect surface finish and minimal chipping.

Mechanical axes

| X axis | 460 mm |

| Y axis | 320 mm |

| Z axis | 660 mm |

| Travel speed X, Y, Z | 15’000 mm/min |

Spindle drive

| Max. grinding wheel diameter | 200 mm |

| Max. Spindle Power | 11,5 kW |

| Max. Number Of Revolutions | 10.500 /min |

Workpiece Data

| Workpiece Length | 270 (350) mm |

| Workpiece Diameter | 3 – 290 (400) mm |

| Max. Workpiece Weight | 50 kg |