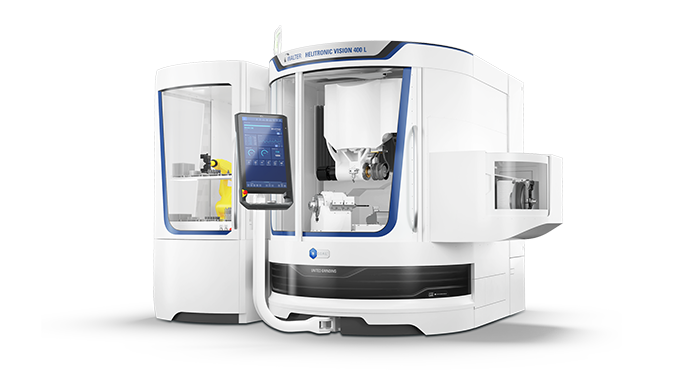

High-end for highest quality requirements

The tool grinding machine HELITRONIC VISION 400 L with C.O.R.E.-Technology produces rotationally symmetrical tools and production parts of complex geometries in high-precision production. It handles tools with a diameter of 3 to 315 mm, a tool length up to 420 mm and a piece weight of up to 50 kg.

Mineral cast gantry design

The WALTER mineral cast gantry design for optimal tool surfaces. The machine provides you with excellent vibration damping, temperature sensitivity, drive dynamics and ultimately grinding precision.

LASER CONTOUR CHECK

The new, innovative Laser Contour Check option offers an intelligent measuring system integrated directly in the tool grinding and eroding machine for the highly accurate, non-contact measurement of various tool parameters on cylindrical tools.

Linear drive

All five CNC axes are equipped with linear drives and are controlled by the integrated high resolution measurement systems. They create exact movements while at the same time creating high dynamics.

Torque drive

The HELITRONIC VISION 400 L has a rotary axis C with a torque drive for very high accuracy and durability.

Torque motor

The rotary axis A as a torque motor with a maximum of 750 min-1. For extended functionality, such as precise profile grinding or background lines.

Motor spindle

The tool grinding machine is equipped with a powerful direct driven motor spindle with a spindle end with a liquid cooling system. Spindle performance is 33 KW.

Mechanical axes

| X axis | 500 mm |

| Y axis | 350 mm |

| Z axis | 700 mm |

| Max Travel Speed X, Y, Z | 50.000 mm/min |

| Swiveling Range C | 400 ° |

Grinding spindle drive

| Max. grinding wheel diameter | 254 mm |

| Max. Spindle Power | 30 kW |

| Max. Number Of Revolutions | 7.800 / 10.000 /min |

Workpiece Data

| Workpiece Length | 420 mm |

| Workpiece Diameter | 3 – 315 mm |

| Max. Workpiece Weight | 50 kg |